DPF Double Piston Flow Comparator

Flow calibration with air at gauge pressure

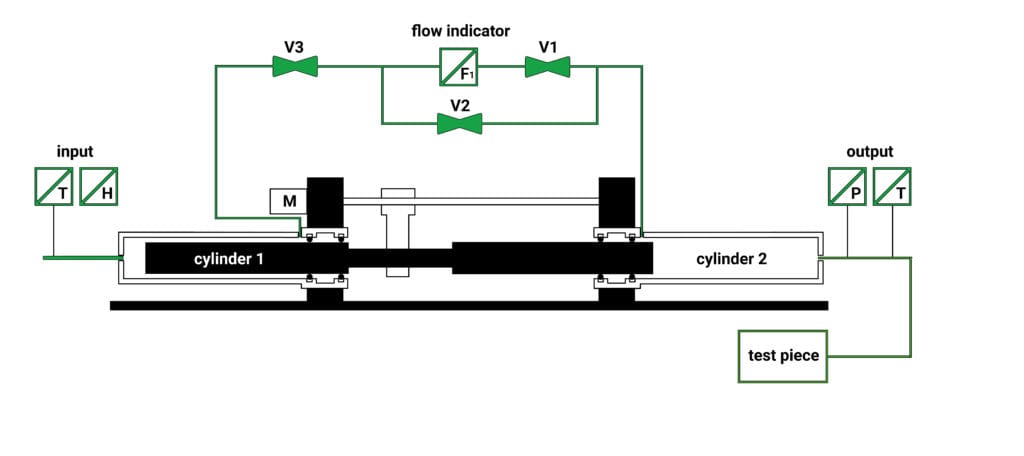

The system is used for generating a volume flow traceable to the SI units

length and time. The calibration device is preferably operated with air, which can be fed with up to 6 bar gauge pressure. The system is used for the calibration of gas meters, sonic nozzles, mass flow meter, LFEs, venturi nozzles and leak test items.

Technical data

DPF120L – Primary standard 120 l/h

| Operating range | 0.25…120 l/h |

| Measurement uncertainty (4…100 l/h) | Type A: ≤ 0.10% (k=2) Type B: ≤ 0.20% (k=2) |

| Measurement time | t > 20 s |

| Medium | Atmospheric air Compressed air Optional: other gases |

| Operating pressure | up to 6 bar gauge pressure (7 bar abs.) |

DPF6000 – Primary standard 6000 ml/h

| Operating range | 6…6000 ml/h |

| Measurement uncertainty (100 ml/h…5000 ml/h) | Type A: ≤ 0.12% (k=2) Type B: ≤ 0.20% (k=2) |

| Measurement time | t > 25 s |

| Medium | Atmospheric air Compressed air Optional: other gases |

| Operating pressure | up to 6 bar gauge pressure (7 bar abs.) |

Measuring principle

The pistons are moved via a spindle with a stepper motor. In the initial state one of the pistons is fully retracted and the other one is fully extended. Using the piston cross-section and the travel speed the flow can be adjusted with high precision. At the end of the calibration process both pistons are in the opposite position to the initial position.

Features

- Measurement uncertainty up to 0.10% (k=2)

- User defined pre-tempering

- Calibrations of test items with compressed air and other gases (option)

- No measurement errors caused by temperature stratification

- Fully adjustable air flow

If you have any questions, please do not hesitate to contact our EP-E service team.