Calibration loop for hydrogen

The current questions in the H2 network …

- How much hydrogen does my process use?

- How much hydrogen was provided by the network operator?

- And how can I be sure that it will be billed precisely?

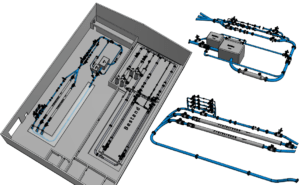

Hydrogen distribution network, our customer, RMA Rheinau GmbH Co. KG, has decided to set up a calibration loop for gas meters. In terms of its size, the system will be the first of its kind in the world. The hydrogen project is funded by the Federal Ministry of Education and Research (BMBF) in order to promote possible solutions for the German hydrogen economy.

“We are pleased to be able to supply the calibration software as well as the relevant measurement technology. Furthermore, critical nozzles of different sizes are in our scope in order to be able to guarantee the return of the measurement technology to a national standard in cooperation with the Physikalisch-Technische Bundesanstalt (PTB).”

Thomas Kappes (CEO)

Key data and scope of services

- Software for measurement data acquisition, calibration and database under LabView

- Flow reference measurement technology consisting of master meters and differential pressure elements

- Individual size measurement technology including data acquisition hardware

- Critically operated nozzles for traceability

Technical specification

| Qmin … Qmax | 5 … 6500 m³/h |

| Pmax … Pmin | 16 barg (ideal 8 barg) … 51 barg |

| Nominal size | DN50 … DN300 |

| Measurement uncertainty for the calibration value of a test item | ≤ 0.3 % (Idealziel 0.2 %) |

What are your requirements in the H2 network?

We support you in your H2 activities and

offer you the appropriate know-how to implement your project.