EoL, R&D & series testing

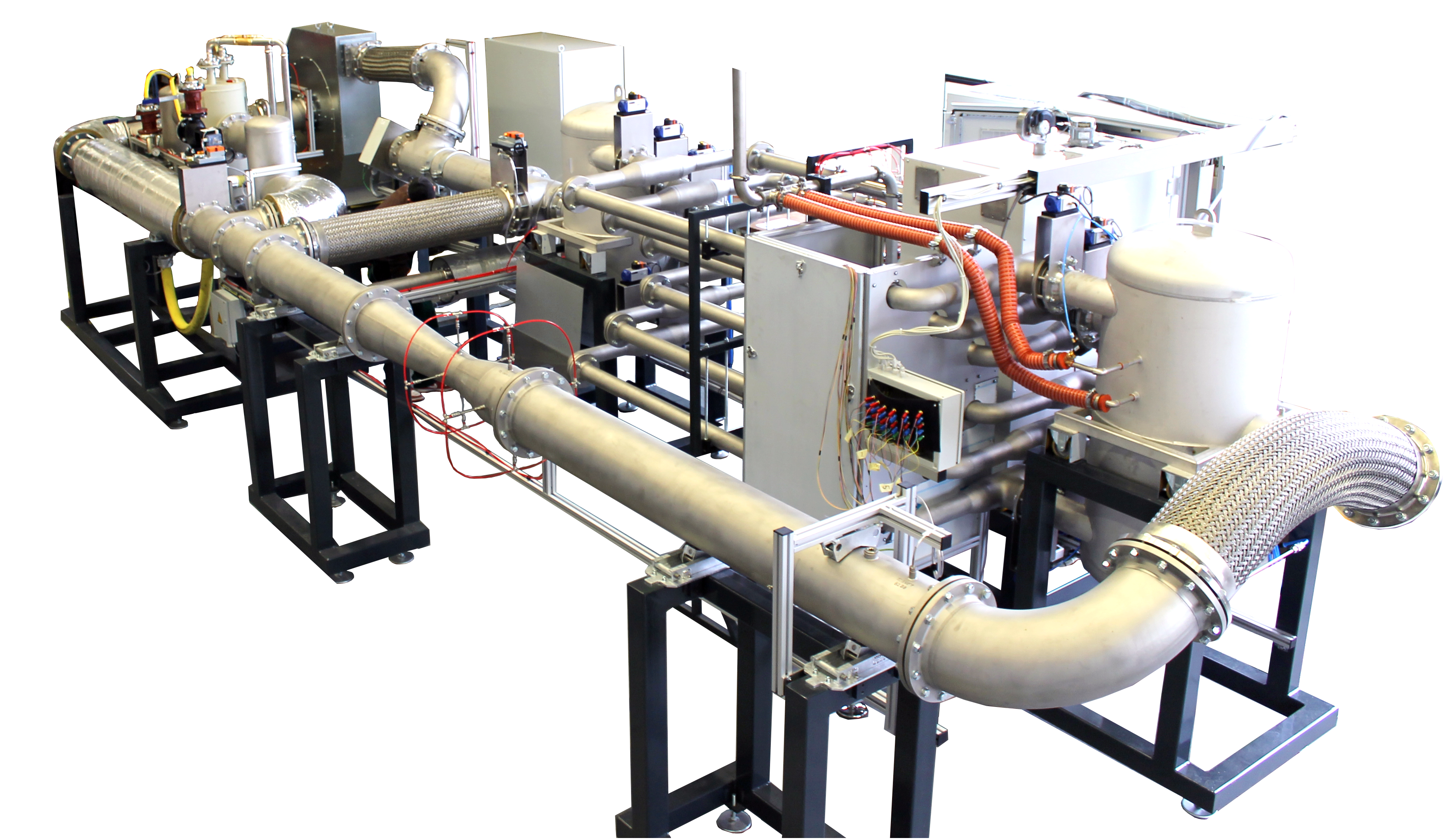

A high series quality requires precision and reliability. Operational and endurance tests are necessary to verifiably guarantee high quality. In the form of selection or random tests, components are tested for fatigue and wear through load tests, e.g. under pressure and temperature changes. The tests are used for the long-term stress test of various materials and products with different pressure curves and temperatures. We build test benches according to your requirements: e.g. for long-term or short-term tests, under static or pulsating test conditions and depending on other factors. Present us your requirements!

- Temperature cylce test

- Pressure cycle test

- Internal pressure cycling test

- (Pulse) high pressure test

- Aging test

- Resistance test

- Production testing (during production)

- Development testing (performance measurement)

- Endurance testing

Application examples for component test benches

Test item examples

- Charge air cooler (heat exchanger)

- Housing under pressure

- Valves

- Automotive component

- Fluid storage container

- Filter housing

- Heaters

- Etc.

Features

Resistance & functional test

Large pressure & temperature ranges

Environmental simulation

Precisely adjustable & reproducible test conditions

Comprehensive specifications

| Temperature test air | Room temperature up to 300 °C |

| Temperature test chamber | -40…200°C |

| Test pressure (internal pressure) | -0.8…6 bar |

| Waveform pulsation | Sine, triangle, trapezoid, (freeform) |

| Frequence pulsation | 0.1…2 Hz (> 1 Hz only sine & triangle) |

| Cycle time pulsation | 0.5…10 s (Sine & triangle) |

| Number of test items | 1…6 (more on request) |

| Volume per test item | Up to 6 l |