Pharma & Medicine

You can also benefit from the extensive experience and knowledge of EPE in measurement and test engineering if your business is in the medical and pharmaceutical industry. Be it standardised test methods, complete test benches for inhaler tests, high pressure tests with water or measuring and controlling components for blood pumps – rely on safety and highest accuracy with EPE.

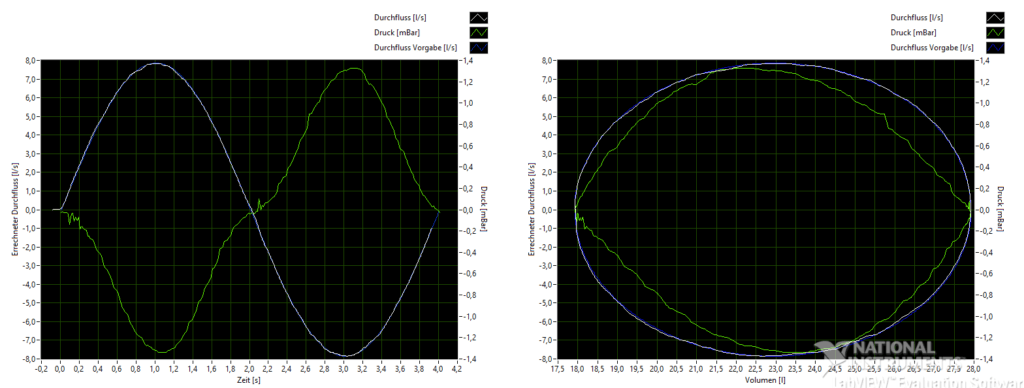

Simulating breathing air flows

Flow generator for the calibration of air flow sensors

The test system is particularly characterized by the generation of stable flows in the low flow volume range. In the medical industry it is used to adjust or calibrate flow sensors, for example to measure human respiration. The human breathing velocity is very fast – the use of the piston system makes it possible to generate high flow rates and to regulate and, if necessary, adjust them at the same time.

Burst test benches, Asthma inhaler test bench

One of our burst test benches is used for pressure tests on inhaler components. In general we manufacture burst test benches for customer-specific pressure ranges with air or nitrogen. The same applies to the medium of water. In our priming system, critical special nozzles check the flow function of, for example, inhalers for powder drugs.

Air volume flows and mass flows can be precisely measured using our LaminarMasterFlow system (LMF®). The core of the LMF® system is a PC-based controller. Alternatively, we use systems based on a laptop with a USB interface to the converter electronics. The controller with power supply and sensor supply is located in a 19″ slot. The measurement track distance and the sensor system are set up separately.

Chemistry

The chemical industry is exactly our element where our extensive experience in redundant test systems and high temperature calibration offers particular advantages.

Tailor made to your specifications:

Flow measurement systems

Our flow measurement systems based on differential pressure (orifices, Venturi nozzles) with the required inlets and outlets are made of stainless steel, just as are the systems with supercritical Laval nozzles. We develop and manufacture special nozzles as tailor-made products in the material of your choice. We can deliver measurement and calibration standards with Laval nozzles with utmost precision – measurement inaccuracy to 0.14% of measured value (k=2). The measurement ranges for these systems start at approx. 1 l/h (10-3 m³/h). With an appropriate compressor (vacuum pump), up to 10,000 m³/h are possible. A test bench with 12 Laval nozzles and dual nozzle grading allows to set 2^12 discrete flow steps (i.e. 4,096 step) in flow increments of the smallest nozzle – at highest accuracy of up to 0.14%.

Our calibration laboratory is specialised in on-site calibrations of various flow measurement systems (irrespective of the manufacturer). This ensures that the measurement element is calibrated in the installation condition when it is subject to real influences and not only to laboratory conditions without environmental influence. We also calibrate measurement systems with air at temperatures of up to 500°C.

Calibration service – DIN EN ISO/IEC 17025 certified

Our laboratory is DKD certified according to DIN EN ISO/IEC 17025. The components of our test benches which come into contact with test media are made entirely of stainless steel. Many years of experience in measurement and calibration technology result in a very high measuring accuracy, e.g. when measuring pressure or flow, to give our customers the best possible advantage.