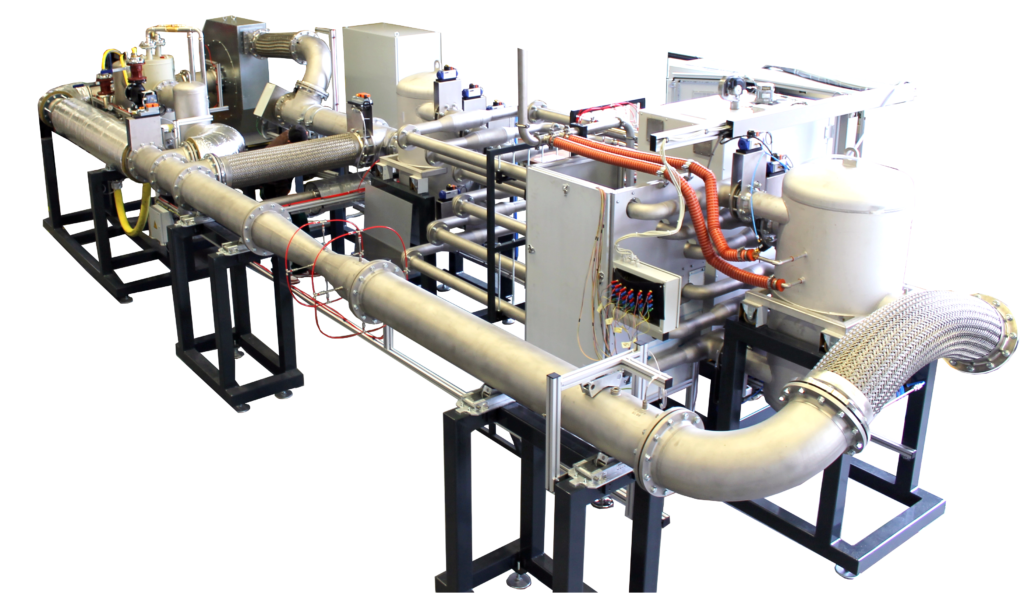

(High-) Temperature Test Bench

Longterm-testing with hot air

In this application the temperature test bench is designed for testing throttle valves with hot air (max. 230°C). The test bench is designed for operation as a closed air circuit with a pressure of 1000 to 3000 mbar abs. The test items are installed in a climatic chamber. The functional resistance of the throttle valves is to be tested against thermal load. Boundary conditions are a cyclic temperature profile for the inlet air and one for the ambient air of the item. Altogether 6 items are tested simultaneously in one test sequence. The throttle valves are to be subjected to identical thermal loads. This includes the same inflow velocity, degree of turbulence and temperature. For this purpose the items are connected in parallel. The system control is done via a PC with precise NI measurement data acquisition hardware and a measurement and control software under LabVIEW.

Technical data

| Air mass flow | 6x (200…1800) kg/h |

| Pressure range | 1000…3000 mbar abs. |

| Temperature test chamber | 30…150°C |

| Temperature profile test air | 20…230 °C |

Features

- “Closed Loop” design for energy-saving operation at overpressure

- Any temperature profile of the test air between 20…230 °C

- Any temperature of the test environment between 30…150 °CC

- Parallel connection of up to 6 test items

- Simulation of the driving profile of a motor vehicle with regard to air mass flow