SMF® – SonicMasterFlow®

Highly precise flow measurement of gases and air

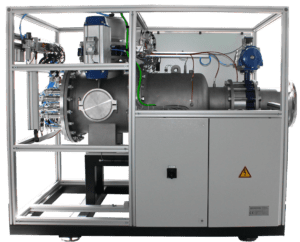

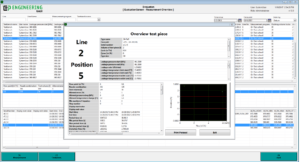

The SMF® – SonicMasterFlow® series are calibration systems for high-precision flow measurement of air and other gases (optional) (volume and mass flows) using critically operated laval nozzles. The modular design for a wide range of flow ranges with clever options makes the nozzle test benches ideal for a wide variety of applications. Operation is simple and safe thanks to an intuitive user interface, the automatic nozzle combination and internal system checks.

SMF® – SonicMasterFlow® systems are complete nozzle test benches that work with automatically controlled nozzle systems in drum design. The modular structure allows you to choose the optimal combination for your own application from different drum sizes and different nozzle sets. The application spectrum ranges from the lowest flows from 0.0025 up to 10,000 m³/h.

Technical data

| Flow range | 0.0025…10,000 m³/h |

| System accuracy | 0.3% MV (DAkkS) 0.2% MV (PTB) |

| Nozzle accuracy | 0.25% MV (DAkkS) 0.15 % MV (PTB) |

| Recalibration period | Up to 10 years for laval nozzles |

Applications

- Calibration of various flow sensors (gas meters, air mass meters, MID, LFEs, orifices, venturis, ultrasonic gas meters etc.)

- Calibration as an end-of-line or development test at the manufacturer

- Alignment level for valves, actuators, flow meters, etc

Measurement principle

With the flow at the speed of sound through Laval nozzles, a constant volume flow can be set very precisely and quickly. By combining different critical nozzles, a wide variety of flows can be generated. With 8 critical nozzles e.g. 2^8 = 256 different flows can be generated. For uniform coverage of the flow range, a binary staggering of the nozzles is recommended. If, however, other nozzle sizes make more sense due to the application, customer-specific adaptation of the nozzle set is possible.