VMF® – VenturiMasterFlow®

Flow measurement of air and gases

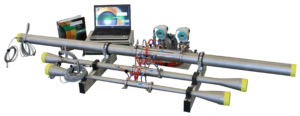

We develop and manufacture venturi tubes and nozzles as individual components or as complete VMF® systems. The VenturiMasterFlow® measuring system, or VMF® for short, is used for the precise measurement of air or gas volume and mass flows. The core of the VMF® system is the FlowProcessor, a PC system with appropriate data acquisition hardware. The PC system can either be a laptop, embedded system or, in the case of larger measuring systems, a rack PC. The software developed under LabVIEW is operated either via the touchscreen or with a mouse and keyboard. Volume flow measurements up to 100,000 m³/h venturi nozzles with low permanent pressure loss flow measurement for gases with high temperatures are possible.

Technical specification

| Flow range | Up to 100.000 m³/h |

| Measurement accuracy | Up to 0,5% MV |

| Responsiveness | < 10 ms |

| Temperature range | Customer specific |

Applications

- Transfer standard for flow calibrations

- Volume flow measurement of hot gas, e.g. exhaust gases

- Gas conditioning

Measurement principle

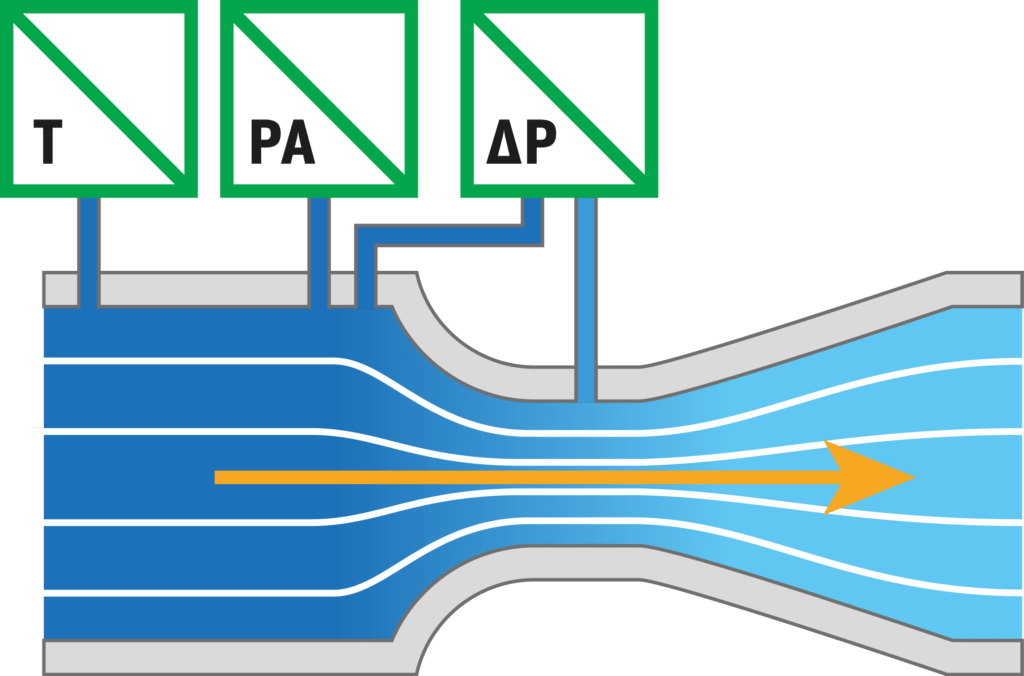

At the narrowest point of the pipe, the dynamic pressure (dynamic pressure) is maximum when a gaseous or liquid medium flows through the Venturi nozzle. The static pressure is minimal. The velocity of the flowing medium increases in the ratio of the cross-sections as it flows through the narrowing cross-section, since the same amount flows through everywhere. At the same time, the pressure in the sampling tube drops. This creates a differential pressure, which is then used in various measuring devices or for the suction of liquids or gases.

If you have any questions, please do not hesitate to contact our EP-E service team.