HPT – Heat Pump Test Bench

Testing of heat pumps through dynamic temperature & humidity control

The HPT heat pump test bench is a closed-loop test bench for functional testing of air-to-water heat pumps according to DIN EN 14511. The advantageous closed-loop design uses an insulated chamber with conditioning units for temperature and humidity outside the chamber. The conditioned air runs in a closed circuit (closed-loop). This design provides excellent, uniform temperature and humidity conditions throughout the chamber. The temperature and humidity control of the different climate points according to DIN EN 14511 is accurate and dynamic. An optimized safety concept enables safe tests with refrigerants with low GWP.

Technical data

Conditioning measuring chamber

| Temperature | -25…+50°C |

| Relative humidity | 10…92 % r.H. |

| Wet-bulb temperature | 8…+48°C |

| Flow air | 1000…4000 m³/h |

Conditioning raw water

| Temperature | 7…70°C |

| Flow water | 3…55 l/min |

Conditioning heating water

| Temperature | 6…10°C |

| Flow water | 2…48 l/min |

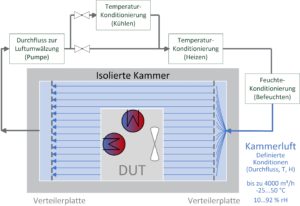

Measuring principle – advantageous closed loop design

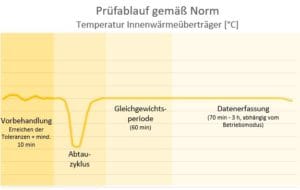

The measuring points defined in DIN EN 14511 reflect the different operating states of the heat pump at outside temperatures of -15°C to 20°C (see DIN EN 14511-3). Both the temperatures and the corresponding wet-bulb temperatures of the external heat exchanger are specified in the standard. The guarantee of a good accuracy of the test bench and the consideration of the inertia of the ambient air is achieved by defining permissible deviations of the arithmetic average and the single values. The most important point in temperature control is the defrosting process of the heat pump, which takes place regularly during operation to prevent the evaporator from freezing. For this reason, DIN EN 14511 specifies a test procedure which always includes the following steps: Preparation phase, defrosting process, compensation time and actual measurement and data acquisition.

Two distributor plates realize a laminar flow through the test chamber. This leads to an optimal temperature and humidity uniformity. The dynamic temperature and humidity control can be monitored particularly well during the defrosting process, which leads to disturbances in the control loops. The standard stipulates that temperature and wet bulb temperature must be within the tolerances again after at least 10 minutes (see DIN EN 14511-3). With the EPE closed-loop control this is no problem.

Features

- Precise and dynamic temperature and humidity Control: For realistic simulation of real operating conditions

- Laminar flow through the test chamber:

For optimal temperature and humidity uniformity - Optimized safety concept (ATEX Zone 2):

For safe testing with low GWP refrigerants - Option: Heating water and raw water conditioning:

Simulation of a complete realistic test setup - Option: Multi-chamber test benches:

For separate simulation of different rooms (exterior, technical and living space)

Are you interested in further details?

In our data sheet manager you will find our brochures and data sheets.