National calibration / transfer standards

EPE calibration standards are transfer standards with the highest possible measurement uncertainty, the measurement results of which can be traced back directly to the SI units m and s. Over the past few years, we at EPE have designed a range of transfer standards that are designed for use in calibration laboratories.

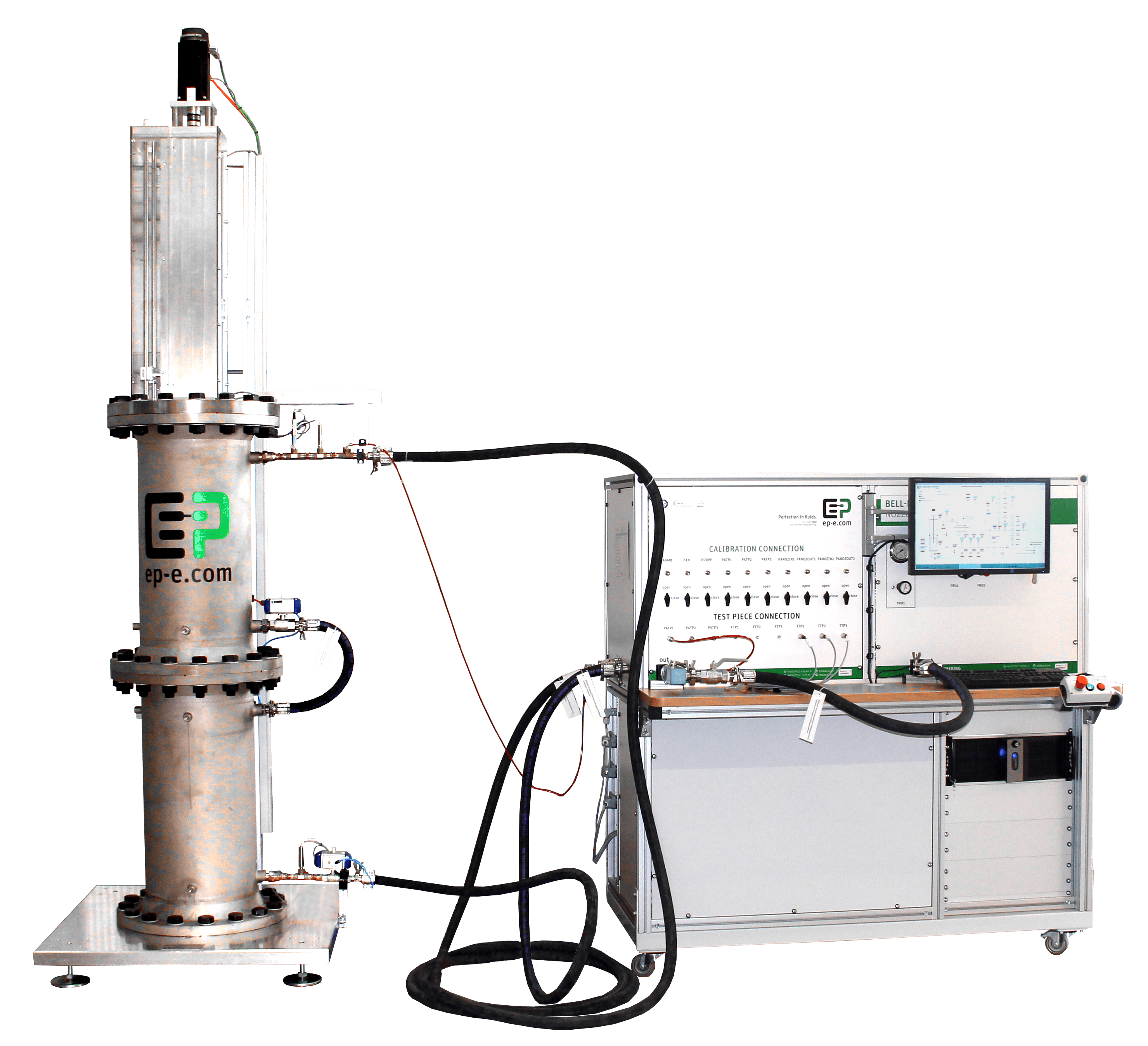

As a technology partner of the Physikalisch-Technische Bundesanstalt (PTB) in Braunschweig, our solutions are based on the highest standard. One of the most important tasks of PTB is the realization and transfer of the legal units volume (m³) and flow rate (m³/h) or mass (kg) and mass flow (kg/h) of flowing gases, also in the area of application at high pressures. Various piston test benches and a gas measuring bell are available as standard. The EPE primary standards have been used successfully in various national, metrological institutes worldwide for years.

Calibration systems

Applications

- Primary standards for national metrological institutes and calibration laboratories

- Provision of national standard measuring devices

- Calibration standard for critical nozzles, venturi nozzles, gas meters, differential pressure sensors, etc. in the atmospheric pressure range

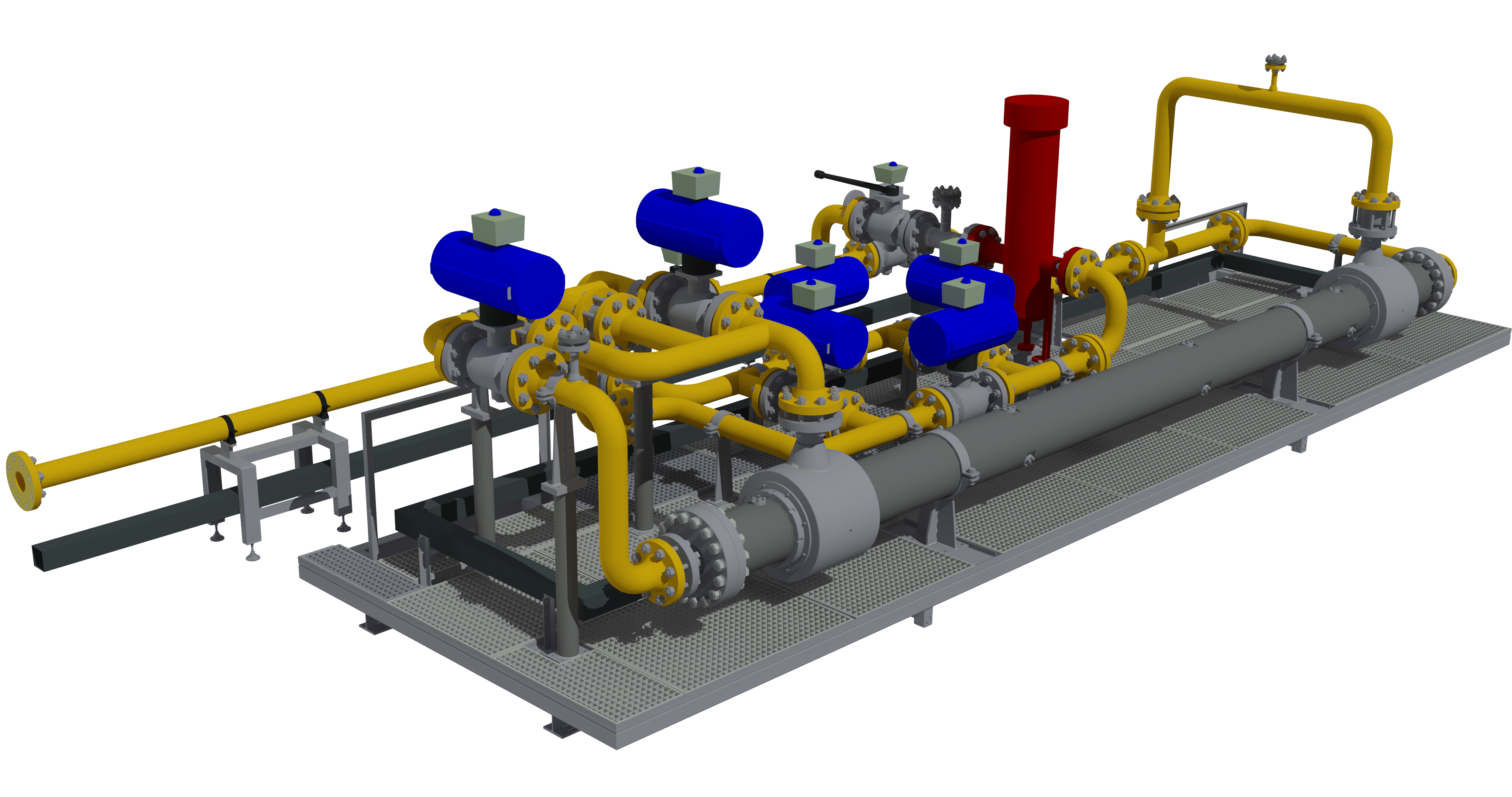

- Calibration of flowmeters for air and natural gas

- Calibration of flowmeters for hydrogen (under development)

Check according to regulations

Measurement and calibration systems not only for gases, but also for liquids!

Furthermore, we offer test stands or measuring systems for testing a measuring device in compliance with the underlying calibration or system-relevant regulations.

Two concrete examples:

- Test benches for the adjustment and calibration of heat meters according to the test instructions.

GM-P 7.2 heat meter – flow sensor

As of May 19, 2020

- Mobile gas samplers for representative gas sampling to determine the gas quality in the gas network, ATEX-compliant and PTB-approved.

Features

Lowest measurement uncertainty, ISO 9001 and DAkkS accredited

Traceable to SI units of length and time

Partner of the Physikalisch-Technische Bundesanstalt (PTB), member of the German Calibration Service (DKD)

Specification

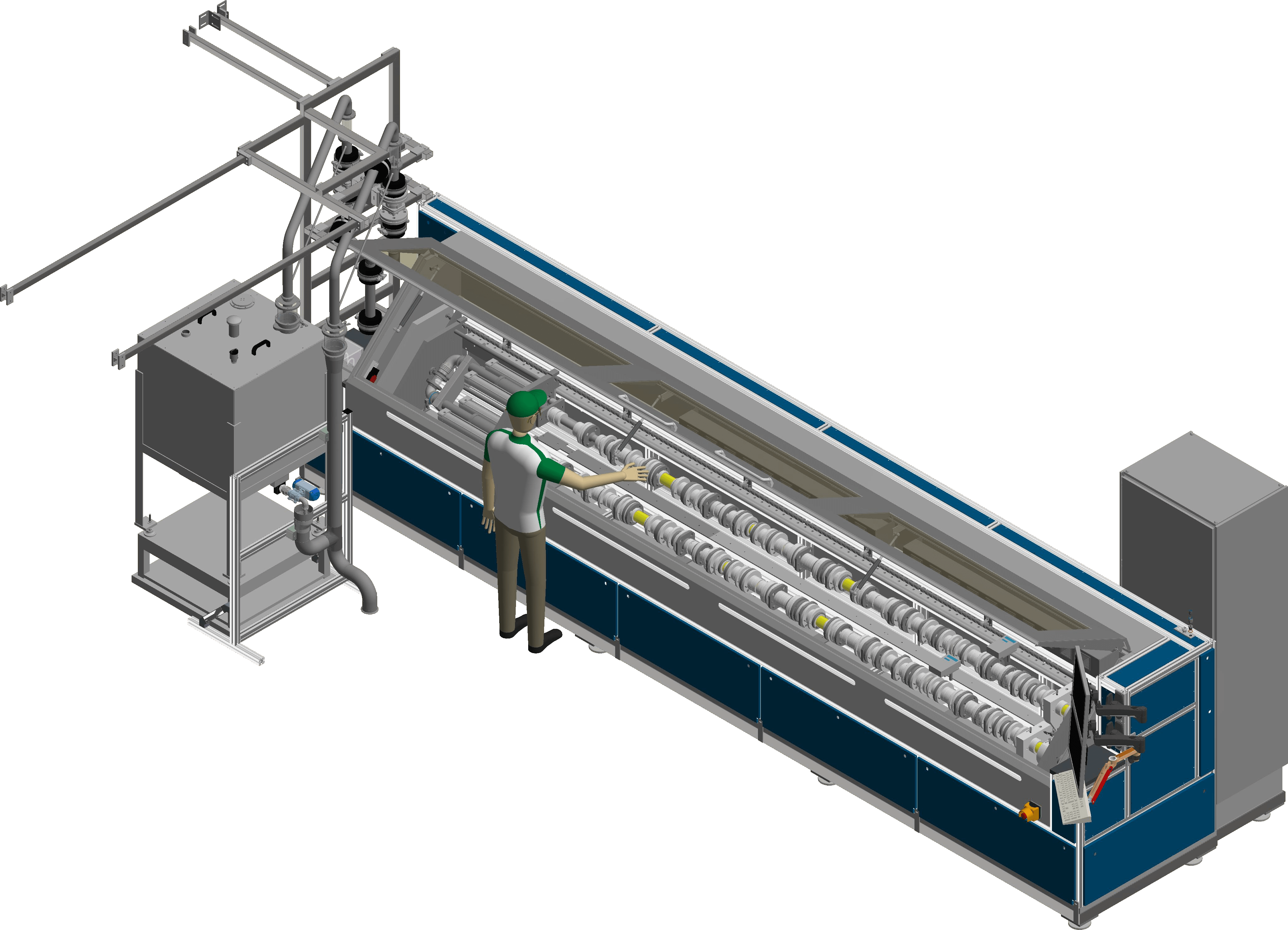

| BP – Bell Prover | BPP – Bell Piston Prover | DPF – Double Piston Flow Comparator | HPPP – High Pressure Piston Prover | |

|---|---|---|---|---|

| Measurement section | Bells cylinder and standing vessel | Bell piston encapsulated in pipe section | Double pistons in cylinders | Piston in pipe section |

| Measurement principle | Displacement of an enclosed air volume by sinking the bell cylinder | Displacement of an enclosed air volume by moving the bell piston using a stepper motor | Displacement of an enclosed air volume by moving the double piston using a stepper motor | Passive, by a driven piston (driven by the gas flow) in a honed tube |

| Flow range | 0.1…300 m³/h | 2…16.000 l/h | 1.5 ml/h…120 l/h | 8…480 m³/h |

| Measurement uncertainties | 0.06…0.25 % MV | 0.08…0.3 % MV | 0.1…0.5 % MV | up to 0,07 % MV |

| Pressure range | Atmospheric | Atmospheric up to partly 40 bar overpressure | Atmospheric up to max. 6 bar overpressure | 15 to 100 bar overpressure |

| Medium | Air | Air, other gases (optional) | Air, other gases (optional) | Natural gas |

| Temperature range | 18…25 °C | 18…25 °C | 18…25 °C | 18…25 °C |

| Key Benefit | Lowest measurement uncertainty due to traceability to SI units length and time | Lowest measurement uncertainty due to traceability to SI units length and time | Low flow measurement with the lowes measurement uncertainty | Lowest measurement uncertainty with overpressure calibration of natural gas |